Robotics automation is revolutionizing various sectors, from manufacturing to healthcare. This overview explores the multifaceted nature of robotic systems, their applications, and the challenges and opportunities they present. It delves into the intricate programming languages, design considerations, and implementation strategies crucial for successful integration.

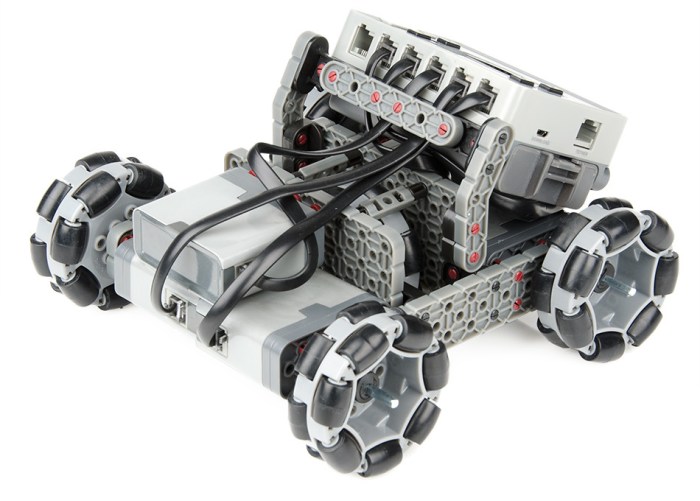

The core components of robotic automation systems, such as robotic arms, sensors, and controllers, are examined, along with their historical evolution. Different types of robotic systems, including industrial robots and collaborative robots, are detailed, highlighting their unique functionalities and specific applications.

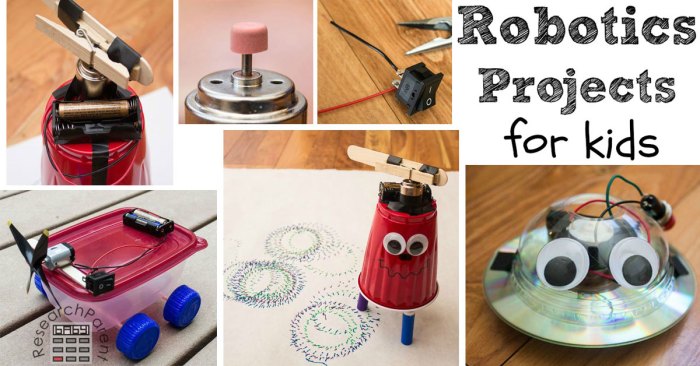

Introduction to Robotics Automation

Robotics automation is a rapidly evolving field that utilizes robots to perform tasks that were previously done by humans. This automation streamlines processes, enhances efficiency, and improves safety in various industries. It allows for the handling of repetitive, hazardous, or intricate operations with precision and consistency.

Definition of Robotics Automation

Robotics automation is the application of robots in a controlled environment to perform tasks automatically, without direct human intervention. This involves designing, implementing, and maintaining robotic systems to execute specific procedures or functions. The key is the automation of a process, using robots as the primary tools.

Key Components of a Robotic Automation System

Robotic automation systems typically comprise several key components working in concert. Understanding these components is crucial for successful implementation and maintenance.

- The robot itself: This encompasses the mechanical structure, actuators, sensors, and the processing unit that enables the robot to move and manipulate objects.

- The control system: This is the brain of the system, responsible for programming, coordinating, and monitoring the robot’s actions. It dictates how the robot interacts with its environment.

- The end-of-arm tooling (EOAT): These tools, attached to the robot’s end effector, are tailored to specific tasks. They enable the robot to perform a wide array of operations, such as welding, painting, or picking and placing.

- The software: This includes programming languages and software applications that define the robot’s movements and actions, as well as data management systems for tracking and analyzing operations.

- The surrounding environment: The physical space in which the robot operates, including its infrastructure and safety protocols.

Types of Robotic Automation Systems

Robotic automation systems come in diverse forms, catering to various applications.

- Industrial robots: These are large, heavy-duty robots commonly used in manufacturing settings for tasks like welding, painting, material handling, and assembly. They are often programmed for highly repetitive and structured tasks.

- Collaborative robots (cobots): Cobots are designed for collaborative work alongside human operators. They are typically smaller, lighter, and safer than industrial robots, enabling them to work in closer proximity to humans, increasing efficiency in assembly and packaging lines.

- Service robots: These robots are designed for a variety of service tasks in environments such as healthcare, logistics, and security. Examples include surgical robots, delivery drones, and security patrol robots.

Historical Evolution of Robotics Automation

The development of robotics automation has been a gradual process, driven by technological advancements and evolving industrial needs.

- Early stages: The initial stages focused on simple, repetitive tasks. Early industrial robots were primarily programmed for fixed sequences of movements.

- Advancements in control systems: Improvements in control systems and programming languages led to more sophisticated and flexible robots.

- Emergence of cobots: The rise of collaborative robots marked a significant shift towards safer and more flexible automation solutions.

- Current trends: Ongoing research and development continue to push the boundaries of robotics, focusing on areas like artificial intelligence, machine learning, and advanced sensors.

Role of Programming in Robotic Automation

Programming is essential for defining the robot’s actions and behavior.

- Programming languages: Various programming languages, such as Robot Operating System (ROS) and specific robot manufacturer languages, are used to create instructions for the robot.

- Task-specific programming: Programming is tailored to specific tasks, enabling the robot to perform complex operations with accuracy and precision.

- Simulation and testing: Simulating robot movements and testing programs before deployment ensures efficient execution and avoids potential errors.

Applications of Robotics Automation

Robotics automation is rapidly transforming various industries, streamlining processes, and boosting efficiency. From manufacturing assembly lines to complex healthcare procedures, robots are taking on increasingly sophisticated tasks, freeing up human workers for more strategic and creative endeavors. This evolution necessitates a deeper understanding of how robots are impacting different sectors.

Manufacturing Applications

Robotics automation has become integral to modern manufacturing. Robots excel at repetitive tasks, ensuring consistency and accuracy in production. This translates to increased output and reduced errors compared to human labor. Specific applications include welding, painting, assembly, and material handling. For instance, robotic arms are frequently used in automotive manufacturing to assemble car parts with unparalleled precision.

This precision leads to higher quality products and reduced production time.

Logistics and Warehousing Applications

The efficiency gains in logistics and warehousing are substantial due to robotics automation. Automated guided vehicles (AGVs) and robotic arms are now commonly used to manage inventory, sort packages, and transport goods. Sophisticated systems can navigate complex warehouse environments and optimize routes, maximizing space utilization and minimizing handling time. This results in significant cost savings and improved order fulfillment speed.

Healthcare Applications

Robotics automation is increasingly utilized in healthcare settings. Surgical robots provide enhanced precision and dexterity for minimally invasive procedures, potentially leading to faster recovery times and reduced complications. Robots are also used in rehabilitation therapy, assisting patients with physical exercises and providing support for mobility. Further, robots are utilized for tasks like dispensing medication and monitoring patients.

Agricultural Applications

Robotics automation is beginning to transform agricultural practices. Autonomous tractors and harvesters are being employed to increase efficiency and productivity in large-scale farming. Robots can perform tasks such as planting, weeding, and harvesting with greater precision than human labor, optimizing resource utilization. This technology can be particularly valuable in areas with challenging terrain or limited access.

Customer Service Applications

While less prominent than in other sectors, robotics automation is making inroads into customer service. Chatbots and virtual assistants are being deployed to handle routine inquiries, providing 24/7 support and freeing up human agents for more complex issues. This can improve response times and enhance customer satisfaction, especially in situations with high call volumes.

Benefits and Challenges of Robotics Automation

Robotics automation is rapidly transforming industries, offering significant advantages while simultaneously presenting complex challenges. Understanding these benefits and hurdles is crucial for informed decision-making in the adoption of robotic systems. The integration of robotics brings forth opportunities for increased productivity, improved safety, and enhanced efficiency, but also necessitates careful consideration of economic, social, and ethical implications.

Advantages of Implementing Robotics Automation

Robotics automation offers a range of benefits across various sectors. Increased efficiency and productivity are key advantages, allowing for faster production cycles and higher output. The consistent performance and reduced errors associated with robotic systems lead to greater quality control and fewer defects. Furthermore, robotic automation can alleviate the need for human intervention in hazardous environments, boosting safety for workers.

- Enhanced Productivity and Efficiency: Robotic automation can perform tasks with greater speed and precision than humans, leading to increased output and reduced production time. This translates into higher efficiency and lower production costs. For example, in automotive manufacturing, robotic arms can assemble car components significantly faster than human workers, leading to higher production rates and reduced labor costs.

- Improved Safety and Reduced Risks: Robots can work in hazardous environments, such as those involving dangerous chemicals or radioactive materials, minimizing human exposure to risks. This is particularly beneficial in industries like nuclear power or chemical processing.

- Increased Quality and Consistency: Robots perform tasks with consistent precision and accuracy, reducing errors and variability in products. This translates to higher product quality and fewer defects.

- Reduced Labor Costs: While initial investment in robots can be substantial, their long-term cost-effectiveness often surpasses human labor, especially for repetitive or physically demanding tasks. The lower labor costs can be a significant economic benefit.

Economic Benefits of Robotic Automation

The economic impact of robotics automation is substantial. Reduced labor costs and increased production are key factors. Moreover, improved efficiency leads to higher profits and potentially lower prices for consumers. The potential for new industries and jobs also presents a considerable economic opportunity.

Robotics automation is rapidly changing manufacturing and various industries. Considering a thoughtful gift for Mom this Mother’s Day? Check out some stunning jewelry options at Mother’s Day jewelry gift for a present that’s both beautiful and meaningful. Ultimately, these advancements in robotics automation are shaping the future of work and daily life.

- Increased Productivity and Profitability: Automation often translates to higher output and lower production costs, leading to increased profits and a stronger economic position for businesses. This can be seen in industries like logistics, where automated warehouses and delivery systems increase efficiency and reduce reliance on manual labor.

- Job Creation in Related Fields: While some jobs may be displaced by automation, the development, maintenance, and operation of robotic systems create new job opportunities in engineering, programming, and maintenance roles.

- Potential for New Industries: Robotics automation opens doors for the creation of entirely new industries, such as autonomous vehicles and advanced medical technologies.

- Lower Prices for Consumers: Increased efficiency and reduced production costs can translate to lower prices for goods and services for consumers.

Social and Ethical Implications of Robotics Automation

The implementation of robotics automation raises important social and ethical concerns. Job displacement is a prominent issue, requiring proactive strategies for workforce retraining and adaptation. The potential for bias in algorithms and the ethical implications of autonomous systems also need careful consideration.

- Job Displacement and Workforce Adaptation: Automation may lead to job displacement in certain sectors, necessitating workforce retraining and adaptation programs. For example, the rise of self-driving trucks has the potential to displace long-haul truck drivers, demanding proactive measures to provide alternative employment opportunities and skills training.

- Bias in Algorithms and Ethical Concerns: Algorithms used in robotic systems may reflect existing societal biases, leading to discriminatory outcomes. The ethical implications of autonomous weapons systems and other potentially harmful applications must be carefully considered.

- Impact on Human-Robot Interaction: The increasing integration of robots into society raises questions about the future of human-robot interaction and the potential for dependence on robotic systems.

Technical Challenges in Deploying Robotic Automation Systems

Several technical challenges impede the wider adoption of robotic automation. High initial investment costs and the complexity of integrating robots into existing systems are significant obstacles. Ensuring the reliability and safety of robotic systems is also crucial.

- High Initial Investment Costs: The purchase and implementation of robotic systems often require significant upfront capital investments, which can be a barrier for smaller businesses.

- Integration Complexity: Integrating robots into existing manufacturing processes or workflows can be challenging, requiring substantial engineering and programming expertise.

- Maintaining Reliability and Safety: Ensuring the reliability and safety of robotic systems is crucial to prevent accidents and downtime. This involves robust design, rigorous testing, and ongoing maintenance.

Safety Considerations Associated with Robotic Automation

Safety is paramount when deploying robotic automation. Robust safety protocols and procedures are essential to prevent accidents and ensure the well-being of both workers and the public.

- Safety Protocols and Procedures: Implementing robust safety protocols and procedures is essential for preventing accidents and ensuring the well-being of workers and the public. This includes establishing clear safety zones, implementing emergency stop mechanisms, and providing appropriate training to operators.

- Risk Assessment and Mitigation Strategies: A thorough risk assessment is necessary to identify potential hazards associated with robotic automation and implement effective mitigation strategies. This may involve incorporating redundant safety systems or implementing fail-safe mechanisms.

Programming Languages for Robotics Automation

Robotic automation relies heavily on programming languages to instruct robots on specific tasks. These languages, designed for precision and repeatability, bridge the gap between human intent and robotic action. Understanding these languages is crucial for developing and deploying effective robotic systems.Different programming languages cater to various aspects of robotic control, from low-level hardware interaction to high-level task definition.

Choosing the appropriate language depends on factors like the complexity of the task, the specific robot model, and the programmer’s familiarity.

Common Programming Languages, Robotics automation

A variety of programming languages are employed in robotic automation. Their choice depends on the robot’s capabilities and the specific application. Some of the most prevalent include:

- Python: Python’s versatility and extensive libraries make it a popular choice for robotics. Its readability and ease of use facilitate rapid prototyping and development, especially for complex tasks involving machine learning and AI integration. Python’s rich ecosystem of libraries for numerical computation and data visualization makes it well-suited for tasks like path planning and data analysis.

- C++: Known for its performance and control over hardware, C++ is often used for robotic systems demanding high speeds and low latency. Its ability to interact directly with hardware makes it suitable for real-time control applications. It is a preferred choice for tasks requiring tight control over robot movements and intricate hardware interactions.

- MATLAB: MATLAB is particularly well-suited for robotics applications involving simulation, modeling, and control system design. Its built-in toolboxes and functions facilitate the development of complex control algorithms and the simulation of robot behavior. This is frequently used in research and development environments.

- ROS (Robot Operating System): ROS is a framework, not a language, but it plays a significant role in robotics. It provides a platform for building complex robotic applications, offering tools for communication, sensor integration, and task management. It fosters interoperability and standardization across various robotic components.

Robotic Programming Language Syntax and Structure

Robotic programming languages share fundamental structures similar to other programming languages. They typically involve defining variables, controlling flow, and performing calculations. These elements are used to specify actions, parameters, and sequences for the robot.

Example (conceptual):“`// Declare a variable for robot arm positionposition = (10, 20, 30);// Move the arm to the specified positionmoveArm(position);// Check if the end-effector is within a certain toleranceif (distanceToTarget < 0.5) // Grasp the object graspObject(); ```

Examples of Robotic Programming

Robotic programming encompasses various tasks. Some examples include:

- Path Planning: Programming the robot to navigate a predefined path, often avoiding obstacles. This involves defining coordinates, calculating trajectories, and adjusting the robot’s movements.

- Object Recognition: Programming the robot to identify and locate specific objects in its environment. This usually involves using image processing techniques and machine learning models.

- Assembly: Programming the robot to perform precise assembly tasks, such as putting together components in a specific order. This involves detailed instructions for each step and ensuring the robot follows the correct sequence.

Simple Robotic Arm Program

A simple program for a robotic arm might involve moving the arm to a specific point, picking up an object, and moving it to another location.

Example (conceptual):“`// Define initial position of the arminitialPosition = (0, 0, 0);// Define target position for the objecttargetPosition = (10, 10, 10);// Move the arm to the initial positionmoveArm(initialPosition);// Locate and pick up the objectpickObject();// Move the arm to the target positionmoveArm(targetPosition);// Release the objectreleaseObject();“`

Comparison of Programming Languages

The table below provides a concise comparison of the strengths and weaknesses of different robotic programming languages:

| Programming Language | Strengths | Weaknesses |

|---|---|---|

| Python | Ease of use, extensive libraries, rapid prototyping | Performance might be lower in real-time applications |

| C++ | Performance, low-level control, real-time capabilities | Steeper learning curve, more complex to develop |

| MATLAB | Simulation capabilities, control system design tools | Limited direct hardware interaction |

| ROS | Framework for complex applications, sensor integration | Not a language itself, requires other languages |

Design Considerations for Robotic Automation Systems

Robotic automation systems are complex, demanding careful consideration of various factors. A well-designed system optimizes efficiency, reduces errors, and ensures safety for personnel and equipment. Proper planning from the initial design phase is crucial for long-term success.Effective design goes beyond simply selecting components. It involves understanding the specific application, environmental constraints, and safety protocols to create a robust and reliable system.

This section delves into key design considerations, including system specification, end-effector selection, environmental impact, and safety measures.

Designing a Basic Robotic Arm System

A basic robotic arm system can be designed for various tasks, such as pick-and-place operations, assembly, or material handling. The specific purpose dictates the required payload capacity, speed, and precision.For instance, a system designed for picking and placing small components needs a lower payload capacity but higher speed and precision for rapid movement. A system handling heavy parts requires a higher payload capacity and potentially lower speed, focusing on stability.

A well-defined purpose is paramount to specifying the other critical parameters.

Choosing Robotic End-Effectors

End-effectors are crucial for a robotic system’s functionality. They are the tools that the robot uses to interact with the environment. Choosing the correct end-effector depends heavily on the task.Factors to consider include the material properties of the objects being handled, the required gripping force, and the desired precision. For delicate objects, a soft-grip end-effector is crucial.

For rough materials, a gripper with stronger clamping force and material-resistant coating is needed. The ability to change end-effectors is also essential for adaptability to different tasks.

Impact of Environmental Factors

Environmental factors significantly influence robotic automation system design. Temperature fluctuations, humidity, and the presence of dust or debris can affect the robot’s performance and longevity.High temperatures can cause mechanical components to expand and contract, impacting precision and speed. Humidity can lead to corrosion, reducing the system’s reliability. Dust and debris can interfere with sensors and mechanisms, leading to errors or malfunction.

Environmental conditions need careful consideration for a robust and dependable system.

Safety Measures for Robotic Automation Systems

Safety is paramount in robotic automation. Measures should be in place to protect both personnel and the robot itself.These measures include safety fences, emergency stops, and sensors to detect human presence. The robot’s programming should incorporate safety protocols to avoid collisions with people or equipment. Proper training for personnel operating the system is essential for a safe working environment.

Steps Involved in Designing a Robotic Automation System

A structured approach to robotic system design streamlines the process and reduces potential errors.

| Step | Description |

|---|---|

| 1. Define the Application | Clearly Artikel the task the robot will perform, including the type of objects, the required movements, and the desired output. |

| 2. Determine System Requirements | Specify the payload capacity, speed, precision, and range of motion needed for the robot arm. Consider the workspace limitations. |

| 3. Select Components | Choose the robot arm, end-effector, sensors, and other necessary hardware based on the application requirements. |

| 4. Design the Control System | Develop the software and control system to program the robot’s movements and interactions with the environment. |

| 5. Implement and Test | Assemble the system, program the robot, and thoroughly test the system under various conditions to ensure functionality and safety. |

| 6. Integration and Maintenance | Integrate the system into the existing workflow and establish a maintenance plan for the long-term operational efficiency. |

Implementation Strategies for Robotics Automation

Integrating robotic automation into existing workflows requires a systematic approach. Careful planning and execution are crucial to ensure a smooth transition and maximize the benefits of the automation. This involves not only the technical aspects of the robot integration but also the human element of training and support.Implementing robotic automation is a multifaceted process that demands attention to detail and a proactive approach to potential challenges.

This includes the critical steps of workflow analysis, personnel training, successful implementation examples, maintenance strategies, and troubleshooting procedures. The process is iterative and often requires adaptation to real-world conditions.

Integrating Robotic Automation Systems into Existing Workflows

A thorough understanding of the existing workflow is paramount for a successful integration. This involves mapping out the current processes, identifying bottlenecks, and evaluating the potential impact of the robotic automation on different stages of the workflow. Detailed documentation of current procedures is essential for the smooth transition to the automated system. This analysis allows for the precise tailoring of the robotic system to meet the specific needs of the workflow.

Steps Involved in Training Personnel to Operate Robotic Automation Systems

Effective training programs are vital for personnel to confidently and competently operate the robotic systems. Training should encompass not only the basic operation of the robotic equipment but also safety procedures, troubleshooting techniques, and maintenance protocols. Comprehensive documentation and hands-on practice are critical elements in ensuring that operators understand the systems and their limitations. Training should be ongoing to adapt to any modifications or new software updates.

Examples of Successful Robotic Automation System Implementations

Several industries have successfully implemented robotic automation systems, leading to increased efficiency and productivity. In manufacturing, robots have automated tasks such as welding, painting, and assembly, reducing errors and increasing output. In warehousing, robots have streamlined order fulfillment and inventory management, improving order accuracy and delivery speed. The success of these implementations hinges on careful planning, precise execution, and adaptability to changing requirements.

Strategies for Maintaining and Troubleshooting Robotic Automation Systems

Regular maintenance is essential to ensure optimal performance and longevity of the robotic automation systems. This involves scheduled inspections, lubrication, and cleaning of the mechanical components. Proactive maintenance minimizes downtime and reduces the risk of costly repairs. A well-defined troubleshooting protocol should be established to quickly identify and address any issues that may arise. Utilizing readily available documentation and consulting with technical support personnel will facilitate timely resolutions.

Flowchart Demonstrating the Stages of Implementing a Robotic Automation System

This flowchart depicts a generalized implementation process. The actual steps and duration may vary based on specific applications.

This flowchart depicts a generalized implementation process. The actual steps and duration may vary based on specific applications.

- Needs Assessment and Planning: Define the automation needs, analyze the existing workflow, and identify potential risks. This stage is crucial for a successful implementation.

- System Design and Selection: Choose the appropriate robotic system, software, and peripherals to meet the specific requirements. This includes the type of robot, programming language, and safety considerations.

- Integration and Testing: Integrate the robotic system into the existing workflow, thoroughly test the system, and refine the programming and procedures.

- Personnel Training: Provide comprehensive training to personnel on operating, maintaining, and troubleshooting the system. This includes safety procedures and emergency protocols.

- Deployment and Optimization: Deploy the system in the production environment and continually monitor its performance. This stage involves iterative adjustments and optimizations to maximize efficiency.

- Maintenance and Support: Implement a maintenance schedule, establish troubleshooting procedures, and provide ongoing support for the system.

Future Trends in Robotics Automation

Robotics automation is rapidly evolving, driven by advancements in artificial intelligence (AI) and machine learning. This evolution is reshaping industries and creating new possibilities for efficiency and productivity. The future of robotics automation is intertwined with the ongoing development and refinement of these technologies.The increasing sophistication of AI-powered systems is enabling robots to perform more complex tasks with greater autonomy and adaptability.

This allows robots to handle more intricate situations, react to unexpected events, and learn from their experiences, ultimately leading to more efficient and versatile automation systems.

AI Integration in Robotic Systems

AI integration is transforming robotic automation by enabling robots to perceive, interpret, and respond to their environment more effectively. This integration leads to robots that can adapt to changing conditions, learn from their experiences, and make decisions autonomously. Examples include robots equipped with computer vision systems for object recognition and manipulation, and robots using natural language processing to understand and respond to human instructions.

AI integration is crucial for achieving greater levels of automation and flexibility in various applications.

Impact of Machine Learning on Robotic Automation

Machine learning is revolutionizing robotic automation by enabling robots to learn from data and improve their performance over time. Robots can be trained to perform specific tasks through machine learning algorithms, enabling them to adapt to variations in their environment and refine their operations. For example, machine learning algorithms can be used to train robots to recognize defects in manufactured products, enabling them to identify and sort out faulty items, improving the quality of the final product and increasing productivity.

Evolving Demands and Applications

Robotics automation is evolving to meet the ever-changing demands of various industries. The demands for increased efficiency, reduced costs, and enhanced safety are driving the development of more advanced and versatile robotic systems. The need for robots to work alongside humans in shared workspaces, also known as collaborative robots (cobots), is increasing, reflecting a shift toward human-robot collaboration.

This evolution reflects a broader trend of integrating automation with human expertise to optimize outcomes.

Future Applications of Robotics Automation

The future of robotics automation encompasses a wide range of applications across various industries. One example is the use of robots in healthcare, where they can assist surgeons in complex procedures, perform repetitive tasks, and monitor patients. Another example is the application of robots in manufacturing, where they can assemble products, inspect parts, and perform other tasks with precision and speed.

Furthermore, robots are becoming increasingly important in agriculture, performing tasks such as harvesting crops, planting seeds, and managing livestock.

Ethical Considerations of Advanced Robotic Systems

As robotic automation becomes more advanced, ethical considerations regarding the use of robots become paramount. Questions arise regarding the potential for job displacement, the responsibility for robot actions, and the need for robust safety protocols. These considerations demand careful evaluation and responsible development of robotic systems to ensure their beneficial use and minimize potential risks. The ethical use of robots is essential for building trust and ensuring a positive impact on society.

Impact on Workforce and Society

Robotics automation is rapidly transforming industries, and its impact on the workforce and society is profound and multifaceted. The potential for job displacement alongside the creation of new roles necessitates careful consideration of workforce retraining and upskilling strategies. Furthermore, the integration of robots can enhance worker safety and introduce novel societal challenges that require proactive responses.

Employment Impacts

The integration of robotics automation has led to both job displacement and job creation across various sectors. Manufacturing, logistics, and customer service are prime examples of industries experiencing significant shifts in employment patterns. The automation of repetitive tasks, previously performed by human workers, can lead to job losses in these areas. However, the demand for specialized roles, such as robotic maintenance technicians, programmers, and data analysts, is also increasing.

A balanced assessment of these factors is critical to understanding the overall impact.

Job Displacement Examples

The automotive industry offers a prime example of job displacement. Automated assembly lines and robotic arms have replaced human workers in many tasks, impacting assembly line workers, welders, and paint technicians. Similarly, in warehousing and logistics, automated guided vehicles (AGVs) and robotic sorting systems have reduced the need for manual labor in picking, packing, and shipping operations. These examples demonstrate the potential for significant job displacement in specific sectors.

Job Creation Examples

Robotics automation has also created new job roles that were not previously envisioned. The development, programming, maintenance, and repair of robots necessitate a skilled workforce of engineers, technicians, and programmers. Furthermore, the rise of data analytics and AI to support and optimize robotic systems has led to the creation of new roles in data science and machine learning.

These emerging roles are essential for managing and utilizing the capabilities of automated systems.

Workforce Retraining and Upskilling

The increasing adoption of robotics automation necessitates a proactive approach to workforce retraining and upskilling. Existing workers in displaced roles require opportunities to acquire new skills in areas such as data analysis, robotics programming, and AI-related fields. Educational institutions and corporations must collaborate to develop relevant training programs that equip workers with the knowledge and skills needed to adapt to the changing job market.

Government initiatives and funding can play a significant role in facilitating these transitions.

Enhanced Worker Safety

Robotics automation can contribute to improved worker safety in several ways. Robots can be deployed in hazardous environments, performing tasks that would be dangerous or impossible for human workers. This includes tasks involving heavy lifting, handling dangerous materials, or working in extreme temperatures. The introduction of robots can significantly reduce the risk of accidents and injuries, safeguarding human workers from potentially harmful conditions.

Robotics automation is rapidly advancing, and its applications are becoming increasingly diverse. While often associated with industrial processes, some intriguing design choices in robotics are inspired by the aesthetic of goth jewelry , particularly in the use of dark and metallic accents. This creative fusion ultimately contributes to the broader evolution of robotics automation.

Societal Impacts

The widespread adoption of robotics automation has potential societal impacts that warrant careful consideration. The potential for widening income inequality is a concern, as the benefits of automation may not be evenly distributed. Ethical considerations surrounding the use of robots in areas like law enforcement and warfare also need careful examination. The need for societal adaptation and proactive measures to mitigate potential risks is crucial for a smooth transition to a robot-integrated future.

Cost-Benefit Analysis of Robotic Automation

Robotic automation presents a significant investment, demanding a meticulous assessment of its financial implications. A thorough cost-benefit analysis is crucial to determining the viability and profitability of such an implementation. This analysis should not only consider the initial capital expenditure but also the long-term operational costs and potential returns.A robust cost-benefit analysis enables informed decision-making, ensuring that the benefits of robotic automation outweigh the associated costs.

This involves a comprehensive evaluation of the return on investment (ROI), considering factors such as labor savings, increased productivity, and reduced material waste. Ultimately, the analysis helps to justify the investment and predict the long-term financial impact.

Financial Implications of Robotic Automation

Implementing robotic automation incurs various financial burdens. Initial capital expenditure for purchasing the robot, installation, and necessary infrastructure are significant upfront costs. Furthermore, ongoing maintenance, repairs, and potential software upgrades add to the operational expenses. The cost of training personnel to operate and maintain the robotic systems should also be considered. Hidden costs, such as downtime due to malfunctions or unexpected maintenance, can significantly impact the financial viability of the automation project.

Factors Affecting Total Cost of Ownership

Several factors contribute to the total cost of ownership (TCO) of a robotic automation system. These factors include the purchase price of the robot, installation costs, software licensing fees, maintenance contracts, and training expenses. The frequency and cost of repairs, potential downtime, and the need for specialized personnel for maintenance are also critical elements. The lifespan of the robotic system and the expected rate of obsolescence also need to be factored into the TCO.

The availability of readily available spare parts is another critical aspect affecting the long-term cost.

Calculating Return on Investment (ROI)

Calculating the ROI for a robotic automation project requires a clear understanding of the benefits and costs associated with the implementation. Quantifying the projected savings in labor costs, increased productivity, reduced material waste, and improved quality are crucial. The projected ROI is calculated by dividing the net profit by the total investment. A high ROI signifies a financially attractive project.

For instance, if a company invests $100,000 in a robotic system and achieves $150,000 in savings over three years, the ROI would be substantial. The formula for calculating ROI is:

ROI = [(Net Profit – Total Investment) / Total Investment] – 100%

Comparison with Traditional Methods

Traditional manufacturing methods often rely heavily on human labor, resulting in higher labor costs and lower output compared to robotic automation. Labor-intensive processes can also lead to higher error rates and inconsistent quality. Robotic automation, on the other hand, provides increased output with consistent quality and reduced error rates. The cost of human labor is often significantly higher than the cost of robotic automation, particularly when considering benefits like 24/7 operation and improved safety standards.

Summary of Cost-Benefit Analysis of Different Robotic Automation Projects

| Project | Initial Investment | Projected Savings | ROI (Estimated) | Time to Payback |

|---|---|---|---|---|

| Assembly Line Automation | $500,000 | $1,000,000 | 100% | 6 months |

| Material Handling Automation | $200,000 | $400,000 | 100% | 3 months |

| Welding Automation | $300,000 | $600,000 | 100% | 5 months |

This table provides a simplified example of the potential cost-benefit analysis for various robotic automation projects. Each project’s specific ROI will vary depending on numerous factors such as the scale of the project, the type of robot used, and the efficiency of the implementation.

Safety and Security in Robotic Automation

Robotic automation systems, while offering numerous benefits, introduce new safety and security concerns. Careful consideration of these aspects is crucial for successful implementation and to prevent potential harm to personnel and damage to property. Understanding potential hazards and implementing robust safety measures are vital for a safe and secure operational environment.Effective safety protocols and security measures are paramount in robotic automation.

This involves anticipating and mitigating risks associated with the machines’ operation, ensuring compliance with regulations, and protecting sensitive data. These precautions contribute to a reliable and trustworthy system, fostering a productive and secure workplace.

Potential Safety Hazards

Robotic automation environments present unique safety challenges, demanding a proactive approach to hazard identification and mitigation. These environments often involve complex interactions between robots, humans, and the surrounding environment. Failure to anticipate and address these interactions can lead to serious injuries or accidents.

- Collisions with humans or objects: Robots operating in close proximity to human workers or moving parts of machinery can lead to collisions. The speed and force of these collisions can result in severe injuries.

- Trapped personnel: Robots with confined workspaces or those that malfunction may pose a risk of trapping personnel. This necessitates implementing lockout/tagout procedures and ensuring sufficient space around robots for safe movement.

- Hazardous materials: Robots used in environments handling hazardous materials, such as chemicals or flammable substances, require specialized safety measures. These measures include proper containment systems, ventilation, and trained personnel.

- Unexpected movements: Malfunctioning robots or unexpected external forces can cause sudden and uncontrolled movements, posing risks to humans and equipment in the vicinity.

Measures to Mitigate Risks

Various strategies can be employed to minimize the safety risks associated with robotic automation. A comprehensive approach encompassing design, operation, and maintenance protocols is essential.

- Safeguarding and enclosures: Physical barriers, fences, or cages can prevent human access to hazardous areas or parts of the robot. These measures limit the potential for contact with moving parts.

- Emergency stops and safety sensors: Integrating emergency stop buttons and safety sensors can allow for immediate intervention if a hazardous situation arises. These devices are crucial for mitigating risks associated with unexpected movements.

- Redundant safety systems: Employing redundant safety systems provides additional layers of protection against malfunctions or unforeseen events. This reduces the likelihood of accidents and ensures continuous operation in a safe manner.

- Training and awareness: Comprehensive training for operators and maintenance personnel is vital. This training should include safety procedures, hazard recognition, and proper use of safety equipment. Ensuring personnel are aware of potential risks is a critical step.

Safety Protocols and Procedures

Establishing clear safety protocols and procedures is crucial for the safe operation of robotic automation systems. This involves documenting procedures and ensuring adherence to these protocols.

- Lockout/Tagout procedures: Implement procedures to isolate equipment before maintenance or repairs to prevent accidental activation of the robot during maintenance. This ensures the safety of personnel working on the equipment.

- Regular safety inspections: Conduct regular inspections of robotic systems to identify and address potential hazards. This includes checking safety sensors, emergency stops, and other safety mechanisms.

- Documentation and record-keeping: Maintain detailed records of safety inspections, training, and any incidents related to robotic automation. This data is vital for ongoing improvement and compliance.

Security Concerns and Data Protection

Robotic automation systems often collect and process sensitive data. Securing this data is essential to prevent unauthorized access and misuse. Robust security measures are needed to protect this information.

- Data encryption: Use encryption to protect sensitive data transmitted and stored by the robotic system. This is a crucial measure for protecting confidential information.

- Access control: Implement access control mechanisms to restrict access to the system and its data. This helps prevent unauthorized access and maintain data confidentiality.

- Regular security audits: Conduct regular security audits to identify and address vulnerabilities in the system. This ensures that the security measures are effective and up-to-date.

Safety Regulations and Standards

Adherence to safety regulations and standards is mandatory in robotic automation environments. Understanding these standards is critical for compliance and safety.

| Regulation/Standard | Description |

|---|---|

| ISO 10218-1 | International safety standard for industrial robots. This standard Artikels safety requirements for robot design, installation, and operation. |

| OSHA (Occupational Safety and Health Administration) | US regulations for workplace safety, covering general safety requirements applicable to robotic automation. |

| Other National Standards | Various national standards exist, reflecting regional requirements. These standards are crucial for local compliance. |

Conclusive Thoughts

In conclusion, robotics automation is rapidly reshaping industries, offering both substantial benefits and complex challenges. The future of robotics automation hinges on innovative solutions to these challenges, ensuring seamless integration into existing workflows and responsible development to address potential social and ethical implications. Ultimately, the strategic deployment of robotic automation promises significant economic advantages and enhanced efficiency.

Questions Often Asked

What are some common safety concerns related to robotic automation?

Safety protocols and procedures are crucial for robotic automation. Potential hazards include collisions with personnel, equipment malfunction, and environmental factors. Robust safety measures, such as physical barriers, emergency stop buttons, and proper training, are essential to mitigate these risks.

How can businesses determine the ROI of a robotic automation project?

Calculating the ROI involves analyzing the financial implications, considering factors like initial investment, maintenance costs, and labor savings. A comparison with traditional methods and a clear projection of long-term benefits are essential to determine profitability.

What programming languages are commonly used in robotic automation?

Common languages include Python, C++, and specific robotic programming languages like Robot Operating System (ROS). The choice depends on the specific robotic system and the desired functionalities.

What are the ethical implications of widespread robotic automation?

Widespread adoption raises ethical concerns about job displacement, the need for workforce retraining, and potential societal impacts. A balanced approach that considers both the economic benefits and the human element is necessary.

![Best RV Portable Waste Tank [2020] | Top Motorhome Reviews Best AI chatbots 2025](https://style.combatgamer.biz.id/wp-content/uploads/2025/06/best-books-thumbnail-1536x1536-1-60x60.jpg)