Garments, from everyday casual wear to formal attire and athletic gear, have evolved alongside culture and technology. This guide delves into the fascinating world of garments, exploring their creation, materials, and the intricate processes behind their design and production. We’ll uncover the history of garments, examining how styles have changed over time and across different cultures.

The discussion also covers the essential aspects of garment construction, the various materials used, and the importance of sustainability and ethical practices in the industry. We will analyze the role of technology in shaping the future of garment manufacturing and explore the global trade landscape.

Types of Garments

Garments serve a multitude of purposes, extending beyond mere protection from the elements. They reflect societal norms, cultural traditions, and individual preferences. Understanding the diverse types of garments, their characteristics, and historical evolution provides a deeper appreciation for human ingenuity and creativity.

Categorization by Purpose

Different garments are designed for specific purposes, ranging from formal occasions to athletic activities. This categorization allows for a structured understanding of the vast array of clothing options available.

- Formal Wear: These garments are typically associated with events requiring a specific level of dress code, such as weddings, galas, and business meetings. Formal wear often includes tailored suits, elegant gowns, and crisp shirts. The characteristics of formal wear often emphasize meticulous tailoring, high-quality materials, and sophisticated designs. Examples include tuxedo jackets, evening gowns, and tailored business suits.

- Casual Wear: This encompasses a wide range of garments suitable for everyday use and informal settings. Casual wear is characterized by comfort and practicality, employing a variety of materials and styles. Examples include jeans, t-shirts, sweatshirts, and casual dresses. The materials and designs often prioritize ease of movement and comfort over formality.

- Athletic Wear: Designed for physical activities, athletic wear is tailored for performance and comfort. Key characteristics include breathability, flexibility, and moisture-wicking properties. Materials such as moisture-wicking fabrics, breathable mesh, and supportive materials are frequently used. Examples include running shorts, athletic leggings, and sports jerseys.

- Workwear: Specific garments designed for various professions, prioritizing safety, practicality, and durability. Workwear frequently includes specialized features like reinforced seams, protective pockets, and safety elements. Examples include mechanic overalls, construction vests, and medical scrubs.

Material Variations

The selection of materials for garments directly impacts the garment’s characteristics, such as comfort, durability, and aesthetics.

| Garment Type | Common Materials |

|---|---|

| Formal Wear | Silk, wool, linen, satin, polyester |

| Casual Wear | Cotton, denim, polyester, nylon, rayon |

| Athletic Wear | Polyester, nylon, spandex, moisture-wicking fabrics, breathable mesh |

| Workwear | Cotton, durable synthetics, leather, canvas, protective coatings |

Evolution of Styles Across Cultures and Time

Garments have evolved significantly across different cultures and historical periods, often reflecting societal values and technological advancements. The evolution of styles reflects the changing needs and aesthetics of various civilizations.

- Ancient Civilizations: Ancient civilizations like the Egyptians, Greeks, and Romans developed distinctive garments reflecting their social structures and artistic sensibilities. Materials and techniques were often influenced by readily available resources.

- Medieval Europe: The Middle Ages saw the emergence of elaborate garments like the tunic and gown, often showcasing social status. Materials and styles varied depending on the region and social class.

- Renaissance and Baroque Periods: The Renaissance and Baroque periods in Europe introduced opulent styles with intricate details and rich embellishments. These periods showcased the flourishing of artistry and craftsmanship in garments.

- Modern Era: The modern era has seen a significant shift in garment styles, driven by technological advancements and changing societal norms. Mass production and new materials have made clothing more accessible and varied.

Garment Construction

Garment construction encompasses the meticulous techniques and procedures employed in creating garments. From the initial patternmaking to the final finishing touches, each step plays a critical role in achieving a well-made, durable, and aesthetically pleasing garment. Understanding these methods allows for greater control over the end product and facilitates efficient production.

Fundamental Construction Techniques

Fundamental garment construction techniques form the bedrock of the craft. These techniques, often learned in sequential order, establish the foundation for producing garments of varying complexity. Mastering these basics allows for the creation of a diverse range of garments and ensures consistency in quality.

- Pattern Cutting: Pattern cutting involves transferring the garment’s design onto a fabric piece, using specialized tools and techniques. This process ensures precision and accuracy in fabric utilization, minimizing waste and maximizing the efficiency of the production process. This process establishes the shape and dimensions of the garment, enabling the seamstress to assemble it accurately.

- Stitching: Stitching is the act of joining fabric pieces together. Various stitching methods, such as straight stitching, zig-zag stitching, and overcasting, are employed depending on the garment and the desired aesthetic. These techniques are critical for creating strong and durable seams that can withstand the stresses of wear.

- Seaming: Seaming involves the joining of two or more pieces of fabric along a seam. This technique requires precision in aligning edges and ensuring a consistent seam allowance. Correct seaming methods directly impact the garment’s fit and overall appearance.

- Finishing: Finishing encompasses the final touches to the garment, including hemming, pressing, and other techniques to enhance the garment’s look and durability. These finishing touches improve the garment’s aesthetic and lifespan. Precise finishing ensures a professional appearance and enhances the garment’s lifespan.

Creating a Simple T-Shirt: A Step-by-Step Process

A simple T-shirt exemplifies the basic garment construction techniques. This detailed process demonstrates the practical application of the previously discussed methods.

- Pattern Preparation: The pattern for the T-shirt is laid out on the fabric, ensuring accurate placement and proper alignment.

- Cutting: Using fabric scissors, the pattern pieces are meticulously cut from the fabric, taking care to avoid damage or misalignment.

- Seaming the Shoulders: The shoulder seams are created by matching corresponding edges and stitching them together using straight stitches, ensuring even tension.

- Side Seaming: Side seams are created by matching edges and stitching, reinforcing the garment’s structure and shape.

- Neckline and Armhole Finishing: The neckline and armholes are finished by using a suitable finishing technique (e.g., serging, zig-zag stitch) to prevent fraying and maintain a clean appearance.

- Hemming: The bottom hem of the T-shirt is created by folding the fabric and stitching along the edge, ensuring a clean and even finish.

- Pressing: Pressing the garment’s seams and folds helps to shape the garment and maintain a neat appearance.

Sewing Methods in Garment Production

Various sewing methods are used depending on the type of garment and the desired outcome. These methods offer different levels of durability and aesthetic appeal.

- Straight Stitch: This fundamental method involves a straight line of stitches, often used for seams and basic construction.

- Zigzag Stitch: This stitch is commonly used for finishing edges and creating decorative effects. Its versatility makes it an indispensable tool for various garment construction needs.

- Overcasting Stitch: This stitch is particularly useful for preventing fabric fraying at raw edges. It’s commonly used in areas like hems, preventing unraveling.

- Serging: A specialized stitch that simultaneously stitches and finishes edges, minimizing fraying. Serging is ideal for high-quality, durable garments.

Tools and Equipment for Garment Construction

A well-equipped sewing station is essential for efficient and high-quality garment construction. The selection of tools depends on the complexity of the project.

| Tool | Description |

|---|---|

| Fabric Scissors | Used for precisely cutting fabric. |

| Sewing Machine | Essential for stitching and seaming. |

| Pins | Used for holding fabric pieces together during construction. |

| Measuring Tape | Essential for precise measurements and pattern making. |

| Seam Ripper | Used for removing mistakes or adjustments. |

| Iron and Pressing Cloth | Used for smoothing out wrinkles and shaping the garment. |

Materials Used in Garments

A crucial aspect of garment production is the selection of appropriate materials. The properties of these materials directly influence the garment’s performance, comfort, and aesthetic appeal. Choosing sustainable and environmentally responsible fabrics is increasingly important for ethical and responsible fashion practices.Fabric selection is driven by a complex interplay of factors. Considerations include desired drape, texture, and color; cost-effectiveness; durability; and the comfort level for the wearer.

Understanding these properties allows designers and manufacturers to create garments that meet specific needs and preferences.

Fabric Properties and Characteristics

Different fabrics possess unique properties, influencing their suitability for various garment types. Cotton, known for its softness and breathability, is a popular choice for casual wear. Polyester, with its durability and wrinkle resistance, is often preferred for activewear and formal attire. Wool, prized for its warmth and resilience, is a classic material for winter garments. Understanding these characteristics allows for informed decisions regarding material selection.

Fabric Comparison Table

| Fabric | Durability | Comfort | Aesthetic Appeal |

|---|---|---|---|

| Cotton | Good, but can shrink or wrinkle | Excellent, breathable and soft | Natural, versatile, and often affordable |

| Polyester | Excellent, highly resistant to wrinkles and damage | Moderate, can feel synthetic and less breathable | Versatile, can be dyed in various colors and patterns |

| Wool | Excellent, durable and resilient | Excellent, excellent insulation and warmth | Luxurious, warm, and sophisticated |

| Linen | Good, but can wrinkle easily | Excellent, breathable and cool | Natural, elegant, and often associated with summer |

| Silk | Good, but can be delicate | Excellent, smooth and luxurious | Luxurious, elegant, and often associated with high-end garments |

Sustainable Materials in Garments

The growing awareness of environmental issues has prompted the exploration of sustainable materials in garment production. These materials often prioritize reduced environmental impact throughout their lifecycle. Examples include organic cotton, recycled polyester, and innovative plant-based fabrics.

- Organic Cotton: Grown without synthetic pesticides and fertilizers, organic cotton reduces the environmental footprint associated with conventional cotton production. This approach lowers water usage and promotes soil health.

- Recycled Polyester: Created from recycled plastic bottles and other materials, recycled polyester reduces the need for virgin resources and minimizes waste. This approach promotes a circular economy.

- Tencel: Derived from sustainably managed forests, Tencel is a biodegradable fabric known for its softness and breathability, with a lower environmental impact compared to some conventional materials.

- Hemp: A fast-growing plant, hemp requires less water and pesticides than conventional crops, making it an environmentally friendly alternative to cotton. Hemp fibers are also exceptionally strong and durable.

- Piñatex: Created from pineapple leaf fibers, Piñatex is a sustainable and eco-friendly alternative to leather. This method reduces waste from pineapple production.

Environmental Impact Comparison

| Fabric | Water Usage | Chemical Usage | Waste Generation | Carbon Footprint |

|---|---|---|---|---|

| Cotton | High | Moderate to High | Moderate | Moderate to High |

| Polyester | Low | Moderate | Moderate | High |

| Wool | Moderate | Low | Low | Moderate |

| Linen | Moderate | Low | Low | Moderate |

| Silk | High | Low | Moderate | Moderate |

The environmental impact of fabric choices is a critical factor in responsible fashion practices. Sustainable materials are increasingly sought after to mitigate the negative effects of conventional production methods.

Garment Design and Aesthetics

Garment design is a multifaceted process that transcends mere functionality. It involves careful consideration of aesthetic principles, fashion trends, and the intended effect on the wearer. Beyond the practicality of covering and protecting the body, garments communicate identity, express personal style, and reflect cultural values. This exploration delves into the core principles and elements shaping garment design.Design principles and elements are fundamental to creating visually appealing and well-structured garments.

Understanding these components allows designers to translate ideas into tangible products that resonate with consumers. Fashion trends, ever-evolving, play a significant role in shaping garment design, pushing boundaries and fostering innovation.

Design Principles and Elements

The foundation of compelling garment design lies in understanding and applying fundamental design principles. These principles dictate the overall structure, proportion, and visual impact of a garment. Elements like line, shape, form, color, and texture contribute to the aesthetic appeal. A thorough grasp of these elements empowers designers to create garments that are both functional and aesthetically pleasing.

- Proportion: Proportion refers to the harmonious relationship between different parts of a garment. Careful consideration of proportion ensures a balanced and aesthetically pleasing silhouette. For example, a well-proportioned dress will complement the wearer’s figure, emphasizing desirable features and minimizing perceived flaws. Imbalances can detract from the overall design.

- Balance: Balance in garment design refers to the visual equilibrium between different elements. Symmetrical designs create a sense of formality, while asymmetrical designs introduce a dynamic and modern aesthetic. Understanding how to achieve balance through the placement of accents, embellishments, or color combinations is crucial.

- Emphasis: Emphasis draws attention to specific parts of a garment or the entire design. It can be achieved through contrasting colors, unique patterns, or strategically placed embellishments. Effective emphasis enhances the visual appeal and creates a focal point.

- Rhythm: Rhythm in garment design refers to the repetition of visual elements, creating a sense of movement and flow. This is often achieved through patterns, lines, or colors that repeat in a predictable or unpredictable manner. Repeating elements can generate a sense of harmony or excitement, depending on the design.

- Unity: Unity refers to the cohesiveness of all elements in a garment design. It ensures that all components work together harmoniously, creating a cohesive and complete aesthetic. Inconsistent elements disrupt the unity of the design, detracting from its overall impact.

Fashion Trends and Influence

Fashion trends exert a powerful influence on garment design. These trends are often driven by cultural shifts, social movements, and technological advancements. Observing and interpreting these trends helps designers anticipate and adapt to evolving consumer preferences.

Garments are essential for everyday life, and the range is vast. Choosing garments that align with personal style and values is key. A great example of this is modest dress, which focuses on clothing choices that prioritize modesty and comfort ( modest dress ). Ultimately, the right garments can reflect individual preferences and beliefs, making them a powerful part of self-expression.

- Sustainability: Sustainability is an increasingly significant trend in garment design, encouraging designers to use eco-friendly materials and production methods. The growing awareness of environmental issues has prompted designers to adopt more sustainable practices, such as utilizing recycled fabrics and reducing textile waste.

- Minimalism: Minimalism continues to be a popular trend, emphasizing simplicity and clean lines in garment design. This trend is often characterized by neutral colors, unadorned silhouettes, and functional designs.

- Bold Colors and Prints: Bold colors and intricate patterns are often incorporated into designs to reflect a contemporary aesthetic. The use of vivid hues and eye-catching prints in garments demonstrates a departure from more conservative styles.

- Technical Fabrics and Innovation: The use of innovative fabrics and construction techniques plays a significant role in pushing the boundaries of garment design. These advancements create garments that are both stylish and functional.

Color, Pattern, and Texture in Garment Design

Color, pattern, and texture are crucial components in conveying a specific mood or message through a garment. The interplay between these elements significantly influences the overall aesthetic appeal and impact of the design.

- Color Psychology: Color psychology plays a significant role in garment design, influencing how the wearer feels and how others perceive them. Certain colors evoke specific emotions and associations, which designers use to create desired responses.

- For example, reds can convey energy and excitement, while blues can evoke calmness and tranquility.

- Pattern: Patterns can add visual interest and texture to a garment, creating a unique aesthetic. Different types of patterns, such as stripes, polka dots, or floral prints, can reflect various styles and trends.

- Texture: Texture plays a vital role in the feel and appearance of a garment. Smooth, rough, or textured fabrics can evoke different sensations and add depth to the design.

Innovative and Unique Garment Designs

Innovation in garment design is constantly pushing boundaries. New materials, construction techniques, and design approaches are constantly emerging.

- 3D-Printed Garments: 3D printing technology is revolutionizing garment design, enabling the creation of complex and intricate designs with unique shapes and textures. The technology allows for the creation of garments that are highly personalized and customized to fit individual needs.

- Smart Clothing: Smart clothing is another area of innovation in garment design. These garments incorporate technology, such as sensors or embedded electronics, to provide functionality beyond traditional apparel. Smart clothing can monitor vital signs, track movement, or even adjust to temperature changes.

- Bio-Inspired Designs: Nature often serves as an inspiration for innovative garment designs. Bio-mimicry allows designers to draw from natural forms and structures, resulting in garments with unique and sustainable qualities.

Garment Manufacturing Processes

Garment manufacturing is a complex process involving numerous stages, from initial design to final delivery. Understanding these stages, the role of technology, and different manufacturing methods is crucial for optimizing efficiency and cost-effectiveness. This section explores the intricate world of garment production.Modern garment manufacturing is increasingly reliant on technology, impacting efficiency, quality control, and cost-effectiveness. Automation, digital design tools, and sophisticated machinery are revolutionizing the industry.

These advancements are allowing for faster production cycles, higher precision, and better quality control, while simultaneously influencing the overall cost structure.

Stages of Garment Manufacturing

The garment manufacturing process typically involves several key stages, each with its specific requirements and considerations. From initial design to final packaging, these stages work in tandem to produce a finished product.

- Design and Pattern Making: This initial stage involves translating the design concept into a precise pattern, which serves as a template for cutting fabric. This step is critical in ensuring the garment fits properly and meets the desired aesthetic. Accurate pattern making is paramount for achieving a satisfactory final product and minimizes waste.

- Fabric Sourcing and Procurement: Sourcing the right fabric is crucial for the final product. Factors like quality, color, texture, and sustainability impact the overall garment. This stage often involves negotiations with suppliers, ensuring the fabric meets the specific requirements of the design and production.

- Cutting: Precision cutting of the fabric is essential to ensure the efficiency and quality of the garment. Different cutting techniques, such as laser cutting or traditional cutting methods, influence the production time and cost.

- Sewing and Assembly: This stage involves assembling the cut fabric pieces into a complete garment. Different sewing techniques, like machine sewing or hand sewing, influence the final product’s quality and aesthetic appeal.

- Quality Control: Quality checks are implemented at various stages to ensure the garment meets the desired standards. Inspection processes involve examining the garment for defects, ensuring proper stitching, and verifying the overall quality.

- Finishing and Packaging: This final stage includes tasks like pressing, ironing, and packaging. This step ensures the garment is presentable and ready for distribution to customers. Careful packaging also contributes to the customer experience.

Role of Technology in Modern Garment Production

Technology plays a pivotal role in modern garment production. Automation and digital tools are transforming the industry, affecting efficiency, quality, and cost.

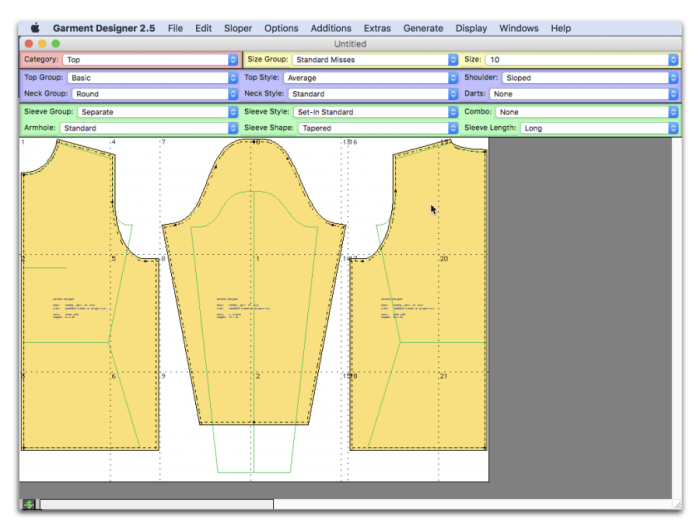

- Computer-Aided Design (CAD): CAD software allows for the creation of detailed garment designs and patterns. It helps designers visualize and manipulate patterns effectively, minimizing errors and improving the design process.

- Computer-Aided Manufacturing (CAM): CAM systems automate cutting and other production processes. This leads to higher precision and increased productivity.

- Robotics and Automation: Automated sewing machines and robots can perform repetitive tasks, increasing efficiency and reducing labor costs. Examples include robotic cutting and stitching machines.

- Digital Printing and Dyeing: These techniques allow for personalized and complex designs, reducing the need for multiple fabric types.

Cutting and Assembling Methods

Various methods are employed for cutting and assembling garments. The choice depends on the garment’s complexity, fabric type, and desired production volume.

- Cutting Methods: Traditional cutting methods involve using scissors and patterns, while laser cutting is used for precision and speed. The choice depends on the fabric type and desired level of accuracy.

- Assembly Methods: Hand sewing, machine sewing, and industrial sewing machines are used to assemble garments. The selection is based on the garment’s design and required precision. For example, delicate fabrics might require hand-sewing techniques.

Comparison of Manufacturing Processes

Different manufacturing processes vary in efficiency and cost. Factors like labor costs, automation levels, and material type significantly influence the final cost.

| Manufacturing Process | Efficiency | Cost |

|---|---|---|

| Traditional Methods | Relatively low | Lower, especially for small-scale production |

| Automated Methods | High | Higher, especially for initial investment, but can decrease long-term costs |

“Efficient manufacturing processes are crucial for achieving profitability in the competitive garment industry.”

Garment Care and Maintenance

Proper garment care is essential for preserving the quality, appearance, and longevity of garments. Consistent and appropriate maintenance practices prevent premature wear, fading, and damage, ultimately extending the life of an article of clothing. This section details various cleaning and maintenance methods, focusing on delicate fabrics and materials, and emphasizes the importance of correct care for each garment type.

Cleaning Methods for Different Fabric Types

Different fabrics require specific cleaning methods to prevent damage and maintain their aesthetic appeal. Wool, for example, is often dry-cleaned, whereas cotton can usually be machine-washed. Understanding these distinctions is crucial for preserving the integrity of the garment. Improper cleaning can lead to shrinkage, discoloration, or even permanent damage to the fabric.

- Dry Cleaning: This method is often recommended for delicate fabrics like silk, wool, and leather. Dry cleaning solvents dissolve dirt and stains without the use of water, minimizing the risk of shrinkage or damage. Specialized dry-cleaning facilities are equipped to handle delicate materials and ensure thorough cleaning. It’s important to check the care label for specific instructions, as certain fabrics may have unique requirements for dry cleaning.

- Machine Washing: Machine washing is a common method for many fabrics, especially those made from cotton, linen, and polyester. Carefully select the appropriate water temperature and cycle for the specific garment. The care label often provides specific instructions, such as the maximum water temperature, the use of bleach, and the recommended cycle type.

- Hand Washing: Hand washing is an excellent choice for delicate fabrics that cannot withstand the agitation of a machine. This method involves gently cleaning the garment in a basin of lukewarm water with a mild detergent. Avoid harsh scrubbing or twisting, which can damage the fabric’s fibers.

- Spot Cleaning: Spot cleaning is ideal for removing stains from specific areas of a garment. Apply a stain remover to the affected area, following the product’s instructions, and gently blot the stain with a clean cloth. Avoid rubbing the stain, which can spread it. Always test the stain remover on an inconspicuous area first to ensure it does not damage the fabric.

Caring for Delicate Fabrics and Materials

Delicate fabrics, such as silk, lace, and chiffon, require special attention during cleaning and maintenance. These materials are prone to damage from harsh chemicals or excessive heat. Gentle handling and specialized cleaning techniques are crucial to preserving their beauty and longevity.

- Silk: Silk garments are often dry-cleaned, as water can cause shrinkage and damage to the delicate fibers. Use a gentle hand when handling silk garments, and avoid harsh chemicals or abrasive materials.

- Lace: Lace is another delicate fabric that requires careful handling. Avoid using harsh detergents or excessive heat, which can damage the intricate patterns and delicate threadwork. Hand washing in lukewarm water with a mild detergent is recommended, followed by gentle drying.

- Chiffon: Chiffon fabrics are known for their sheer and flowing texture. Machine washing chiffon can cause it to lose its shape and drape. Hand washing or dry cleaning are preferred methods for maintaining the integrity of the garment.

Garment Care Table

This table provides a concise overview of recommended care instructions for various garment types.

| Garment Type | Cleaning Method | Water Temperature | Drying Method |

|---|---|---|---|

| Silk | Dry Cleaning | Lukewarm | Line Dry |

| Wool | Dry Cleaning | Lukewarm | Line Dry |

| Cotton | Machine Wash | Warm | Tumble Dry Low |

| Linen | Machine Wash | Cold | Line Dry |

| Leather | Spot Cleaning | N/A | Air Dry |

Importance of Proper Garment Care

Proper garment care is essential for maintaining the quality and longevity of garments. Regular cleaning and maintenance practices help prevent premature wear, fading, and damage, thereby extending the life of the clothing. This translates to significant cost savings over time and reduces the environmental impact associated with frequent garment replacement.

Proper garment care is an investment in the longevity and quality of your clothing.

Garment Sizing and Fit

Accurate garment sizing is critical for a positive customer experience. Proper sizing ensures comfort, allows for freedom of movement, and ultimately contributes to the garment’s longevity. A well-fitting garment enhances the wearer’s confidence and aesthetic appeal. Incorrect sizing, on the other hand, can lead to discomfort, damage to the garment, and a negative perception of the brand.Precise sizing also enables efficient inventory management and reduces returns, contributing to the overall profitability of the garment industry.

It allows for accurate forecasting of demand and optimal production planning, leading to a more streamlined manufacturing process.

Global Sizing Systems

Different countries and regions employ various sizing systems. Understanding these systems is crucial for manufacturers and retailers operating in multiple markets. These variations stem from differing anthropometric data and cultural preferences regarding garment fit.

- The European sizing system (often abbreviated as EU) differs from the American system (US) in terms of measurements and numerical representations. These systems have their own standards and guidelines for measurement, resulting in distinct sizing charts for different garments.

- The Japanese sizing system (often abbreviated as JP) typically utilizes a combination of numerical and descriptive labels. Japanese sizing charts often consider specific body types and preferences, leading to variations in measurements compared to other systems.

- The Asian sizing system encompasses a range of standards across different Asian countries. These systems, although varied, typically prioritize a more tailored fit compared to Western standards.

Body Measurement for Accurate Fitting, Garments

Accurate body measurements are fundamental to ensuring a precise fit. These measurements provide a detailed representation of the wearer’s body shape, facilitating the creation of garments tailored to individual needs.

- Chest circumference, waist circumference, and hip circumference are crucial measurements for determining the appropriate size for garments like tops and dresses.

- Sleeve length, shoulder width, and neck circumference are important for fitting shirts and jackets.

- In addition to these, measurements like inseam length, waist-to-hip ratio, and overall height contribute to a more comprehensive understanding of the body’s dimensions. These detailed measurements help to create garments that accommodate a variety of body shapes and sizes.

Impact of Body Shapes on Garment Fit

Individual body shapes influence how garments fit. Recognizing these differences is essential for creating garments that flatter various body types.

- A pear-shaped body, for instance, typically features wider hips and a narrower bust. Garments should be designed to balance these proportions, potentially using A-line skirts or fitted tops to create a harmonious silhouette.

- An hourglass figure often has a defined waist and similar bust and hip measurements. This body type can flatter a variety of styles, as the balanced proportions allow for versatility in garment design.

- An athletic build, characterized by a leaner frame and broader shoulders, demands garments that offer structure and support while maintaining comfort. Properly designed athletic wear is critical to avoid constriction or undue pressure during movement.

Garment Sustainability and Ethics

The fashion industry is a significant contributor to global environmental and social issues. From textile production to garment disposal, the lifecycle of a garment often leaves a considerable footprint. Addressing these concerns is crucial for creating a more sustainable and equitable industry.

Environmental Impact of Garment Production

Garment production, spanning raw material extraction to final product delivery, exerts considerable pressure on the environment. Textile manufacturing often relies on water-intensive processes, leading to significant water pollution. The use of synthetic dyes and chemicals contributes to chemical runoff and contamination of water sources. Furthermore, the energy consumption throughout the supply chain, from cotton farming to transportation, releases substantial greenhouse gas emissions.

The volume of textile waste generated also poses a substantial environmental challenge.

Ethical Considerations in Garment Manufacturing

Ethical considerations extend beyond environmental concerns. Labor practices in garment manufacturing are critical. Exploitation of workers, including low wages, unsafe working conditions, and long working hours, are unfortunately common issues. The lack of fair compensation and benefits can have detrimental effects on workers’ well-being and their families. Transparency and accountability within the supply chain are paramount for ensuring fair labor practices.

Sustainable and Ethical Garment Practices

Adopting sustainable and ethical practices is vital for mitigating the negative impacts of the fashion industry. One approach involves using organic or recycled materials in garment production. Organic cotton farming reduces the use of pesticides and herbicides, minimizing environmental harm. Recycled materials, such as recycled polyester or plastic bottles, offer a way to reduce reliance on virgin resources.

Furthermore, implementing fair trade practices ensures fair wages and safe working conditions for garment workers. Reducing textile waste through design for durability and repair services can also contribute to a more sustainable approach.

Examples of Sustainable and Ethical Garment Practices

- Transparency in Supply Chains: Companies committed to transparency often publish detailed information about their supply chain, including sourcing details, manufacturing processes, and labor practices. This allows consumers to make informed choices and holds companies accountable for their practices. For instance, some brands publish detailed maps showing the origin of their materials and the factories involved in manufacturing.

- Fair Trade Practices: Fair trade certification ensures that producers receive fair compensation for their work, which promotes ethical labor practices and improves working conditions for garment workers. This can include paying fair wages, providing benefits, and ensuring safe working environments.

- Circular Economy Practices: Promoting a circular economy in fashion aims to minimize waste and maximize resource use. This involves designing for durability and repairability, extending the lifespan of garments, and facilitating the recycling and reuse of textiles. Some brands offer take-back programs for used clothing to facilitate recycling and reuse.

Importance of Transparency in the Garment Supply Chain

Transparency is paramount in the garment supply chain for several reasons. It fosters accountability and allows consumers to understand the origin and production processes of the garments they purchase. This transparency builds consumer trust and empowers them to make informed decisions about their consumption habits. Furthermore, it allows for the identification of potential ethical or environmental violations and encourages corrective actions to improve overall practices.

In essence, transparency in the supply chain strengthens the industry’s commitment to ethical and sustainable practices.

Garment Technology

Garment technology is rapidly evolving, driven by innovations in materials science and manufacturing processes. This evolution is reshaping the industry, offering new possibilities for design, functionality, and sustainability. The integration of advanced technologies into garment production is leading to more sophisticated and adaptable clothing solutions.The incorporation of advanced materials and technologies into garment production is transforming the industry.

Smart fabrics, incorporating embedded sensors and actuators, are redefining garment design and function. This integration allows for personalized experiences and enhanced performance characteristics. Examples of this technology are evident in athletic wear, medical garments, and even everyday clothing. The future of garment technology promises further integration of sophisticated materials and processes.

Advanced Materials and Technologies in Garment Production

Innovative materials are being developed to enhance performance, sustainability, and aesthetics in garments. These materials include high-performance fabrics, such as those with enhanced moisture-wicking properties, wrinkle resistance, or UV protection. Furthermore, advanced technologies like 3D printing and digital textile printing are becoming increasingly prevalent, enabling intricate designs and personalized production. These methods are revolutionizing how garments are designed, produced, and customized.

Impact of Smart Fabrics on Garment Design and Function

Smart fabrics are revolutionizing garment design and function by incorporating embedded sensors and actuators. These features allow for real-time monitoring of physiological parameters like body temperature or heart rate, as well as the ability to adjust garment properties based on these parameters. For example, certain smart fabrics can adapt to changing weather conditions, adjusting insulation or ventilation based on external factors.

This opens new possibilities for personalized comfort and performance enhancement.

Examples of Garments Incorporating Innovative Technologies

Numerous garments are incorporating innovative technologies. Examples include athletic wear with embedded sensors that track performance metrics, providing real-time feedback to athletes. Further examples are smart jackets that adjust their insulation based on ambient temperature and moisture levels, thereby enhancing wearer comfort and safety. Medical garments, designed with advanced materials, can monitor vital signs and provide immediate feedback to healthcare professionals.

Future Trends in Garment Technology

Future trends in garment technology point towards increased personalization, sustainability, and integration of advanced technologies. Personalized garments, designed to cater to individual needs and preferences, are expected to become more commonplace. The use of recycled and biodegradable materials will likely increase, promoting sustainable practices. Furthermore, the integration of advanced technologies like artificial intelligence (AI) and the Internet of Things (IoT) is expected to optimize production processes and enhance consumer experiences.

The development of adaptive garments capable of reacting to the environment or wearer’s needs will also become more prevalent.

Global Garment Trade

The global garment market is a massive and complex network, encompassing design, production, distribution, and consumption across numerous countries. This intricate web is driven by factors ranging from consumer demand to international trade policies, influencing everything from the cost of a t-shirt to the environmental impact of its production. Understanding this market is crucial for businesses, policymakers, and consumers alike.The global garment industry is a significant player in international trade, connecting producers in developing nations with consumers in developed ones.

This exchange facilitates economic growth in both regions, but it also raises important considerations regarding labor practices, environmental sustainability, and fair trade. The interplay of these factors shapes the dynamics of the global garment trade, demanding careful consideration of its impact on all stakeholders.

Garments are essential for everyday wear, but certain styles always stand out. For instance, check out the latest trends in women’s fashion, particularly trendy dresses , which are currently dominating the market. These garments offer a fantastic blend of comfort and style, making them a must-have for any wardrobe.

Overview of the Global Market

The global garment market is vast and diverse, encompassing a wide array of products, from haute couture to mass-produced apparel. Market size is influenced by various factors, including global economic conditions, fashion trends, and consumer preferences. Analyzing these elements allows for a deeper understanding of the market’s dynamics and future prospects.

Role of International Trade

International trade plays a critical role in the garment industry, facilitating the flow of raw materials, components, and finished products across borders. This interconnectedness allows for specialization and economies of scale, contributing to lower costs and greater product variety for consumers. Trade agreements and tariffs significantly impact the cost and accessibility of garments. For example, the reduction of tariffs in the past few decades has led to a greater variety of clothing options at lower prices.

Challenges in the Global Garment Market

Several challenges affect the global garment market. Labor practices, environmental sustainability, and ethical considerations are prominent concerns. The exploitation of workers in developing countries and the detrimental environmental impact of textile production are issues that frequently arise. Furthermore, fluctuating exchange rates, global economic downturns, and political instability can disrupt supply chains and impact profitability.

Opportunities in the Global Garment Market

Despite the challenges, opportunities exist within the global garment market. The increasing demand for sustainable and ethically produced garments presents a burgeoning niche market. Innovation in materials, production processes, and design are creating new avenues for growth and profitability. Consumers are becoming increasingly aware of the environmental and social impact of their purchases, creating an opportunity for companies that prioritize sustainability.

Regional Strengths in Garment Production and Design

Different regions exhibit varying strengths in garment production and design. For instance, some countries excel in low-cost manufacturing, leveraging their labor resources and established supply chains. Other regions may specialize in innovative designs and high-quality materials. Understanding these regional strengths is crucial for businesses seeking to establish or expand their presence in the global garment market. Table below illustrates this point.

| Region | Strengths |

|---|---|

| East Asia (e.g., China, Vietnam) | Low labor costs, established supply chains, diverse manufacturing capabilities |

| Western Europe (e.g., Italy, France) | High-end design, sophisticated manufacturing processes, focus on quality and aesthetics |

| South Asia (e.g., Bangladesh, India) | Competitive labor costs, growing textile industry, diverse manufacturing capabilities |

Garment Industry Trends

The garment industry is constantly evolving, driven by shifting consumer preferences, technological advancements, and global economic factors. Understanding these trends is crucial for businesses to adapt and thrive in this dynamic marketplace. This section explores key developments impacting the industry, including the influence of digitalization and e-commerce, and showcases innovative business models.

Latest Trends in the Garment Industry

The industry is witnessing a rise in sustainable practices, prioritizing eco-friendly materials and production methods. Consumers are increasingly demanding transparency and ethical sourcing, influencing brand choices. Personalized fashion, tailored to individual preferences and needs, is also gaining traction. Furthermore, the industry is embracing technological innovations, including 3D printing and digital design tools, to streamline production and enhance customization options.

Impact of Digitalization on the Garment Industry

Digitalization has revolutionized various aspects of garment production and consumption. Digital design tools allow for faster and more flexible design iterations, enabling quicker response to fashion trends. Virtual fashion shows and online platforms are transforming how brands connect with consumers, creating immersive experiences. Moreover, digital technologies facilitate efficient supply chain management, optimizing inventory control and reducing waste.

This leads to enhanced production efficiency and greater cost-effectiveness.

Emerging Role of E-commerce in the Garment Market

E-commerce is rapidly reshaping the garment market, offering unparalleled convenience and accessibility for consumers. Online retailers provide a wider selection of brands and styles, catering to diverse tastes and preferences. Personalized recommendations and virtual try-on tools enhance the online shopping experience, encouraging purchases. Furthermore, direct-to-consumer (DTC) models are becoming increasingly popular, allowing brands to build stronger relationships with customers and maintain control over pricing and marketing.

This enables brands to bypass traditional retail channels and build direct relationships with customers.

Innovative Business Models in the Garment Industry

Several innovative business models are emerging to address evolving consumer needs and industry challenges. Subscription services allow consumers to access a curated selection of garments on a regular basis, offering flexibility and convenience. Collaborative consumption platforms facilitate the sharing of clothing items, reducing waste and promoting sustainable practices. Furthermore, brands are embracing personalized tailoring services, offering customized garments based on individual measurements and preferences.

This caters to the growing demand for bespoke fashion solutions. Another noteworthy trend is the integration of technology into clothing, such as smart fabrics that monitor wearer activity or provide feedback on performance.

Closing Summary: Garments

In conclusion, garments are more than just clothing; they are a reflection of culture, a testament to human ingenuity, and a window into the future. From the raw materials to the final product, this guide has explored the complete journey of garments, highlighting the intricate details and complexities involved. Understanding the lifecycle of garments allows us to appreciate the craftsmanship and effort behind every piece.

User Queries

What are the most common sustainable materials used in garment production?

Sustainable materials include organic cotton, recycled polyester, linen, and Tencel. These materials often prioritize environmental responsibility and ethical labor practices.

How do different sizing systems vary globally?

Sizing systems differ significantly across regions. Factors like body shape preferences and cultural norms influence these variations. Some systems use numerical values, others rely on measurements.

What are some innovative technologies used in garment manufacturing today?

Innovations include 3D printing for custom designs, smart fabrics with embedded sensors, and advanced cutting and sewing technologies. These improvements often increase efficiency and customization options.

What are the environmental impacts of different fabric choices?

Different fabrics have varying environmental footprints. For example, natural fibers like cotton require significant water resources, while synthetic fibers can contribute to plastic pollution. Understanding these impacts is key to making informed choices.